Shock Wave Engineering Pivot Optimiser™

Graphical Results

Technology

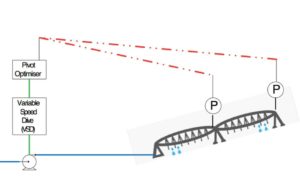

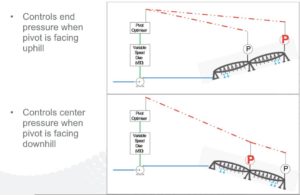

How does the Shock Wave Engineering Pivot Optimiser™ system work?

All pivot pumps are specified such that sufficient pressure is delivered when the end of the pivot is not at its highest point. When the pivot is at lower elevations, excessive pressure is delivered to the pivot. The pivot dissipates this excessive pressure through pressure regulators, installed at every sprinkler. The pivot does a very good job at providing a uniform flow rate to the land. However excess power is used when the pivot is not at the highest point.

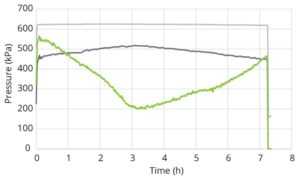

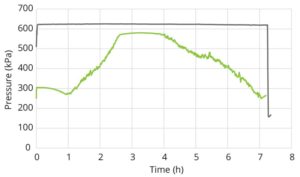

PUMP AND PIVOT PRESSURE

This graph shows the pressure at the pivot centre and end for a typical pivot during a revolution.

Notice how the pressure at the centre experiences a moderate variation and the end experiences a very large variation.

With the pivot nozzles requiring 120 kPa to operate correctly, the actual pressure in this pivot is much higher than necessary.

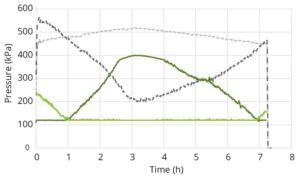

PIVOT PRESSURES MODIFIED BY SHOCK WAVE PIVOT OPTIMISER™

Above you can see pivot pressure controlled by the Shock Wave Pivot Optimiser™. The pivot centre and end pressures are shown in light and dark green.

The original (normal) pressure trace is shown for reference. Notice how the pressure of BOTH the centre and end is kept above 120 kPa.

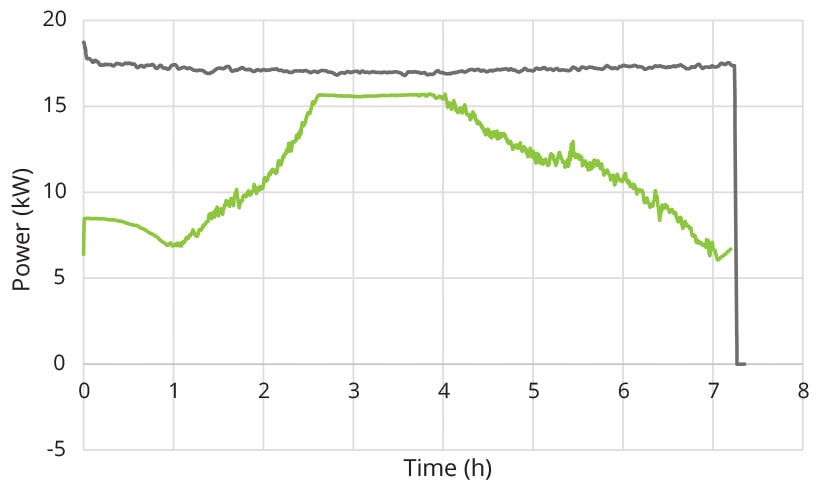

PUMP PRESSURE DURING NORMAL & VARIABLE SPEED DRIVE OPERATION

This shows how pump pressure is reduced by the Shock Wave Pivot Optimiser™. The power consumed by the pump is directly proportional to the pressure.

POWER CONSUMPTION BY THE PUMP

This graph shows pump power consumption at full power versus the Shock Wave Pivot Optimiser™ consumption. The area between the two curves represents the energy savings.

With the pivot nozzles requiring 120 kPa to operate correctly, the actual pressure in this pivot is much higher than necessary.

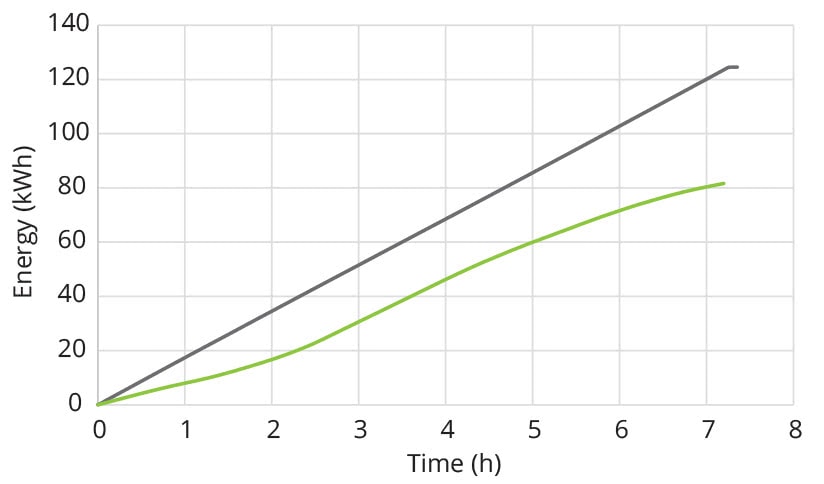

ENERGY SAVING

This indicates power consumed over a full pivot revolution. In this case a saving of 34% was achieved using the Shock Wave Pivot Optimiser™.

Note: These savings were part of a larger project where an overall saving of 60% was achieved for this pivot.